News

No- till cultivation which cultivator to choose?

No- till cultivation which cultivator to choose?

No- till cultivation is gaining increasing popularity among farmers, especially where labour efficiency and minimal fuel consumption are key, without neglecting the quality of the seedbed being prepared.

When opting for simplified cultivation systems, a key element is the right choice of a no-till unit that can effectively cope with the conditions on the farm. It is important that such a unit meets expectations in terms of work efficiency, fuel economy and also guarantees the quality of the seedbed being prepared.

What does no- till cultivation offer?

No- till cultivation has a number of benefits, including a reduction in the number of tillage operations, resulting in time savings, improved field work and the ability to maintain optimum sowing dates, especially over large areas. The reduction in the number of operations also translates into lower fuel consumption, which benefits the environment and the farm budget.

Improved soil structure and porosity is another advantage of no-tillage, resulting in better water retention and increased organic matter content in the upper soil layers. Ploughless cultivation minimises air and water erosion, which is particularly important on light soils and hilly areas.

Which machines for no- till cultivation?

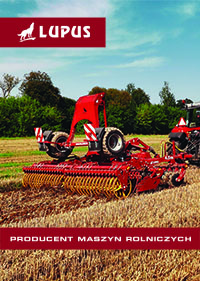

The LUPUS no- till cultivator is the machine type that farmers first choose when switching to reduced tillage. The machine is characterised by its versatility, enabling it to work effectively both during initial, shallow post-harvest soil cultivation and during deeper, more intensive work to thoroughly mix the soil layers at a later stage. The Lupus no- till cultivator also performs effectively during pre-sowing cultivation, especially when sowing in a mulch layer.

The standard working width of the LUPUS no- till cultivator is 3.0m with the possibility of adapting it to 2.5m after unscrewing the outermost extensions together with the complete two tines attached to the frame. There are 2 cultivation systems developed for the machine – the Horsch system and the Delta-flex system, characterised by different tine height and characteristics and angle of attack. Both types have a NON-STOP double spring protection. The cultivator in the basic equipment has hydraulic adjustment of the working depth. The 460 mm diameter discs are mounted on maintenance-free hubs, and the posts are fitted with rubber elastomers for shock absorption and protection against damage. The rear roller can be selected according to soil type.