LUPUS Heavy Duty No-till Cultivator – Your field needs a beast, not a toy.

When the soil is as hard as rock and there are more crop residues than straw in the barn, you need a machine that doesn’t ask questions—it just gets the job done. A machine that bites into the soil with a force the competition can only dream of.

Introducing the LUPUS Heavy Duty Cultivator. This is not another compromise. This is your crushing advantage in the field.

Feel the difference of 2300 kg – Power that impresses

Forget about cultivators that bounce on the field. Our 3-meter LUPUS is 2300 kg of pure power – up to 300 kg more than other machines in this class. What does this mean for you?

Unmatched stability: The cultivator holds the ground perfectly, guaranteeing constant working depth even in the toughest conditions.

Perfect penetration: It handles heavy, compacted, and dry soils without any problems, where lighter machines fail.

Durability for years: A massive 100x100x8 mm frame made of S355 steel, numerous reinforcements, and Italian components guarantee that LUPUS will serve your farm for generations.

No more clogging! Work smoothly, even with high residue levels

We know how frustrating machine clogging is. That’s why we designed LUPUS with an impressive under-frame clearance (85 cm) and large spacing between working sections. The result? The machine easily “swallows” huge amounts of crop residues, ensuring smooth and efficient work. You save time, fuel, and nerves.

LUPUS Heavy Duty Cultivators are perfect for both initial shallow tillage across the entire surface immediately after grain harvest, and for deeper, more intensive work to mix the soil later, or for pre-sowing cultivation in mulch seeding.

EQUIPMENT:

-

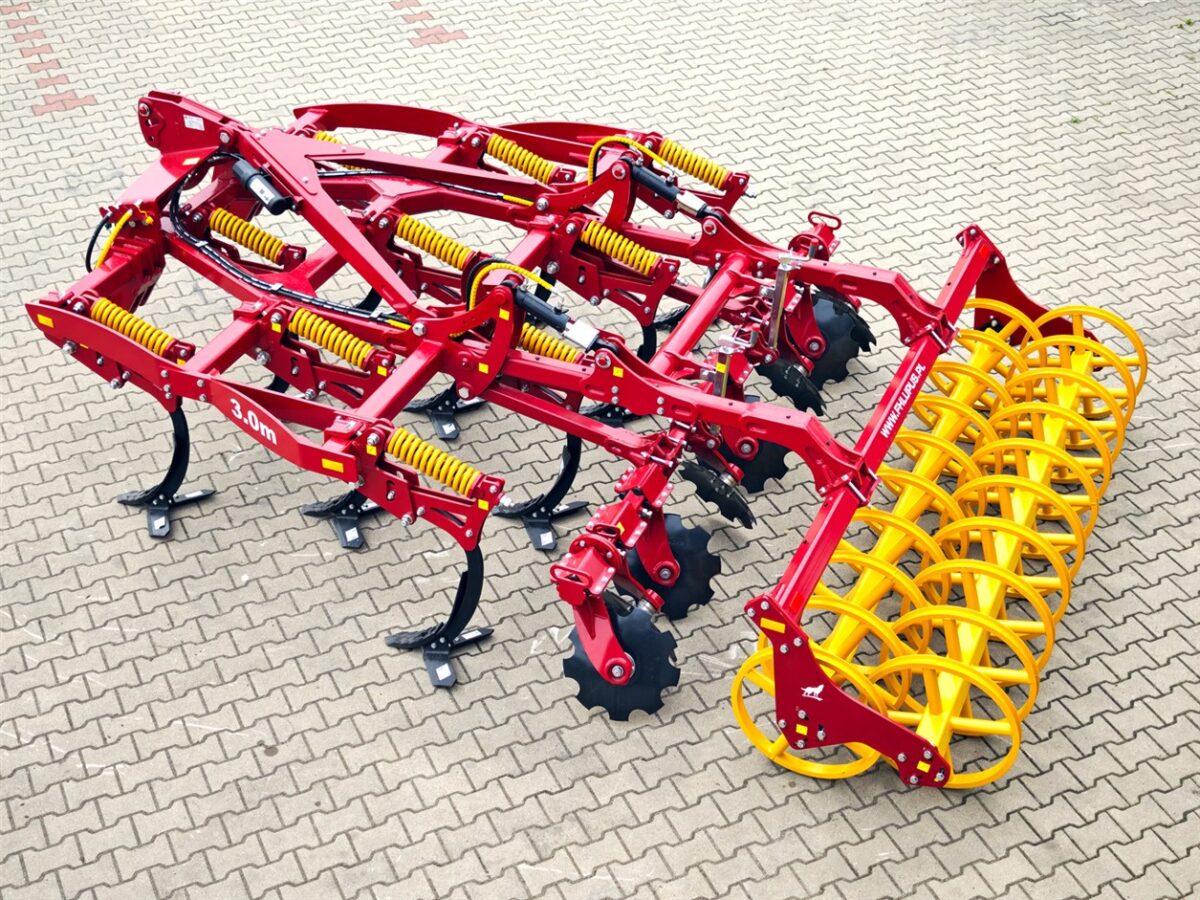

- Working width 2.5m or 3.0m

- 3 rows of tines, Delta or Horsch type

- Spring protection

- Row of leveling discs with rubber protection

- Hydraulic depth adjustment + scale

- Extendable outer discs

- Tubular roller Ø 530 mm

OPTIONS:

- rear roller with diameter Ø 600 mm (V-ring, U-bar ring, T-ring or TANDEM)

- LED lighting

- Mounting plate for catch crop seeder

TECHNICAL DATA:

| WIDTH (M) | WEIGHT (KG) | NO. OF TINES (PCS) | NO. OF DISCS (PCS) | POWER (HP) | MAX. WORKING DEPTH (CM) |

| 2.5 | 1750 | 8 | 6 | from 135 | 30 |

| 3 | 1950 | 10 | 8 | from 150 | 30 |

*The given weight is approximate for the basic version and may vary depending on the configuration. The 3.0 m model with a Ø 600 mm V-ring roller weighs approx. 2300 kg.

Why do farmers choose the LUPUS Heavy Duty Cultivator?

Discover the details that build the advantage.

Three rows of tines – Geometry that works for your profit

This is the heart of the LUPUS cultivator and its fundamental advantage. It’s not just about having three rows of tines – the key is their thoughtful arrangement.

- Precise coverage: Tines are spaced with a 30 cm distance between them. This arrangement guarantees that the absolute entire soil surface across the working width is intensively but evenly loosened and mixed in the very first pass. No “skips” or untreated strips.

- Impressive throughput: A spacious frame with 85 cm under-frame clearance combined with the three-beam layout ensures phenomenal throughput. Even with huge amounts of crop residues, soil and straw flow freely through the machine, eliminating the risk of blockages and downtime.

- Homogeneous soil structure: The result of this geometry is a perfectly mixed, uniform (homogeneous) soil structure. Crop residues are perfectly incorporated into the soil profile, which accelerates their decomposition and fertilizes the site for future crops.

This is not a coincidence, it is purposeful engineering. Every centimeter of this design was created to save your time, fuel, and build the fertility of your land.

One cultivator, two key tasks – Unmatched versatility

LUPUS is a 2-in-1 machine that adapts to your needs:

- Shallow stubble cultivation (up to 15 cm): You attach the side wings (shares), creating a powerful goosefoot. You perfectly undercut the stubble across the entire width, destroy weeds, mix residues, and limit water evaporation.

- Deep loosening (up to 30 cm): You remove the side wings and work with the chisel point alone. With powerful force, the machine crushes and aerates the soil at great depth, breaking the plow pan and preparing ideal conditions for plants with deep root systems. This is work that effectively replaces the plow.

Armored protection against stones – Double spring protection

Do not fear working on stony fields. Each LUPUS tine is protected by a reliable, double spring protection system. This system effectively absorbs impacts, protecting the frame and working elements from damage. It means peace of mind and certainty that the machine will not let you down.

Perfectly level field – Row of leveling discs

Behind the tines works a section of leveling discs, mounted on rubber shock absorbers. Their task is to perfectly level and consolidate the soil and evenly distribute crop residues. Thanks to extendable outer discs, you obtain a perfectly smooth surface across the entire working width.

LUPUS Heavy Duty Cultivator is a solid construction.

The machine frame is made of 100x100x8 profile from hard S355 steel with numerous approvals and quality certificates, plus mostly 15 and 20 mm plates, also only hard and certified S355. Numerous reinforcements were applied to the frame in the form of plate reinforcement triangles, profile offsets, and #12 plate overlays from the bottom and top. Since the machine carries very heavy loads, the headstock was also designed to be bolted and very robust while possessing a unique Design. V-shaped stays made of 20 mm plate with side reinforcements and a coupling plate from the top. All pins and bolts have anti-rotation protection.

Hydraulic working depth adjustment

Hydraulic adjustment of the cultivator’s working depth guarantees the operator even greater comfort and more possibilities. The scale ensures optimal control of the working depth.

Rear roller of choice.

The LUPUS Heavy Duty Cultivator in the basic version is equipped with a tubular roller with a diameter of 530 mm. Optionally, we offer rollers: V-ring, T-ring, U-bar ring with a diameter of 500 and 600 mm, and tandem rollers.

FIELDWORK WITH OUR CULTIVATOR.

BUY DIRECTLY FROM THE MANUFACTURER

LUPUS – Factory & Showroom: ul. Mleczarska 6, 06-400 Ciechanów, POLAND

About us: We are a manufacturer operating in the agricultural sector since 2008. We organize international transport directly to your address. Transport costs are calculated individually based on your location.

CONTACT & ORDERS: Feel free to contact us to arrange the details: 📞 WhatsApp: +48 798 988 179 📧 E-mail: export@fhlupus.pl

BUY DIRECTLY FROM THE MANUFACTURER

LUPUS – Factory & Showroom: ul. Mleczarska 6, 06-400 Ciechanów, POLAND

About us: We are a manufacturer operating in the agricultural sector since 2008. We organize international transport directly to your address. Transport costs are calculated individually based on your location.

CONTACT & ORDERS: Feel free to contact us to arrange the details: 📞 WhatsApp: +48 798 988 179 📧 E-mail: export@fhlupus.pl

You may also like…

Disc harrow LUPUS

BUY DIRECTLY FROM THE MANUFACTURER

LUPUS – Factory & Showroom: ul. Mleczarska 6, 06-400 Ciechanów, POLAND

About us: We are a manufacturer operating in the agricultural sector since 2008. We organize international transport directly to your address. Transport costs are calculated individually based on your location.

CONTACT & ORDERS: Feel free to contact us to arrange the details: 📞 WhatsApp: +48 798 988 179 📧 E-mail: export@fhlupus.pl

Heavy Tine Harrows LUPUS (5, 7, and 9-section)

BUY DIRECTLY FROM THE MANUFACTURER

LUPUS – Factory & Showroom: ul. Mleczarska 6, 06-400 Ciechanów, POLAND

About us: We are a manufacturer operating in the agricultural sector since 2008. We organize international transport directly to your address. Transport costs are calculated individually based on your location.

CONTACT & ORDERS: Feel free to contact us to arrange the details: 📞 WhatsApp: +48 798 988 179 📧 E-mail: export@fhlupus.pl

Hydraulic Folding Disc Harrow BTH

BUY DIRECTLY FROM THE MANUFACTURER

LUPUS – Factory & Showroom: ul. Mleczarska 6, 06-400 Ciechanów, POLAND

About us: We are a manufacturer operating in the agricultural sector since 2008. We organize international transport directly to your address. Transport costs are calculated individually based on your location.

CONTACT & ORDERS: Feel free to contact us to arrange the details: 📞 WhatsApp: +48 798 988 179 📧 E-mail: export@fhlupus.pl