News

What to use for sowing sunflower? 4-row HMS seed drill – field tests.

What to use for sowing sunflower? 4-row HMS seed drill – field tests.

There are many manufacturers of seed drills on the market that are technically very similar to each other.

A keen eye will immediately notice that they differ in details that do not affect the quality of work. One such model caught our eye – the HMS 4F Pinadisc Jumbo 4-row seed drill. Its importer is the Lupus company from Ciechanow.

80-100 HP – this is the power requirement of the HMS 4F Pinadisc Jumbo drill. As a hint, it is a heavy machine, so it is better to combine it with tractors of 100 HP and above.

Pinadisc Jumbo 4F is a 4-row maize seed drill , that can also be used for sowing sunflowers. The 4-row seed drill is manufactured by the Turkish company HMS.

We tested how this machine, which is still a novelty on our market, performs during the sowing of sunflower in the so-called flower. This work took place on a field prepared under no-till. The machine had sections spaced 75 cm apart, the plant (seed) density set at 70,000 plants per hectare and the sowing coulters prepared to work at a depth of 6 cm.

4-row seed drill with fertiliser tank from INOX – 800 l.

Drive to the two boxes mounted to the left and right of the fertiliser tank is via a chain transmission from the left hand wheel of the seed drill. Based on the spreading table, the fertiliser application rate can be set as a guide.

On the machine we tested, our attention was immediately drawn to the 800 litre stainless steel fertiliser hopper. It is divided into two parts, which are equipped with sieves. This, of course, prevents clods getting into the spreading units. The fertiliser granules go into the double-disc coulters mounted on spring legs. These should operate a few centimetres below the sowing coulters. Changing their working depth is trivial, as two bolts simply need to be unscrewed and tightened.

For the work in reduced tillage

The HMS 4F Pinadisc Jumbo 4-row seed drill has a substantial weight of 1150 kg. Thanks to this robust construction and the disc coulters, the machine can be used for reduced tillage. On the other hand, the robust seeding sections require considerable physical strength when securing them for transport and unlocking them before sowing. A rod with a specially shaped tip is used for this purpose. This is an important operation and should not be underestimated. An approach of the type – it’s not far, I’ll move slowly to the other field – can end in a serious failure, including detachment of sections. It is therefore necessary to immobilise all sections before transport.

Each seeding unit is mounted on a parallelogram, allowing it to copy the surface of the field. This is assisted by a spring-loaded pressure adjustable by means of a screw. There is a clear scale with numbers next to it, which makes it easier to set them uniformly. An important component of each section’s precision seed drill is the chisel and the two spreader screens just behind it. The role of the chisel is to push aside stones, in front of the double disc coulter which bites into the soil. The scraper screens, on the other hand, are designed to remove any obstacles such as clumps of crop residue in front of the coulter feeler wheels. This prevents the coulter feeler wheels from being tamped down, which would reduce the sowing depth. The chisel should be set flush with the working depth of the two-disc coulter and the disking screens should be set at 2 cm above the soil surface. . The chisel should be set flush with the working depth of the double disc coulter and the dispersion screens should be set 2 cm above the soil surface.

Vacuum seeding system – HMS 4-row seeder.

The HMS 4F Pinadisc Jumbo, which we tested, is a classic precision seed drill based on a pneumatic seeding system. A fan driven from the tractor’s PTO (540 rpm) creates a vacuum which, in the seeding apparatus, holds the seed in the disc holes. The sudden absence of this suction (in the right place) causes the seed to fall off cyclically and into the soil. This layout requires the maintenance of a constant vacuum, the value of which, as read on the vacuum gauge, should be between 40 and 60 mbar. During operation, this must absolutely be kept in mind. Any time the PTO shaft is engaged, the vacuum in the system will be lost and the seed will fall off the discs. For this reason, the fan drive should not be switched off on the headland, as switching it on just before the seed drill is lowered into work will cause the seed to start too late

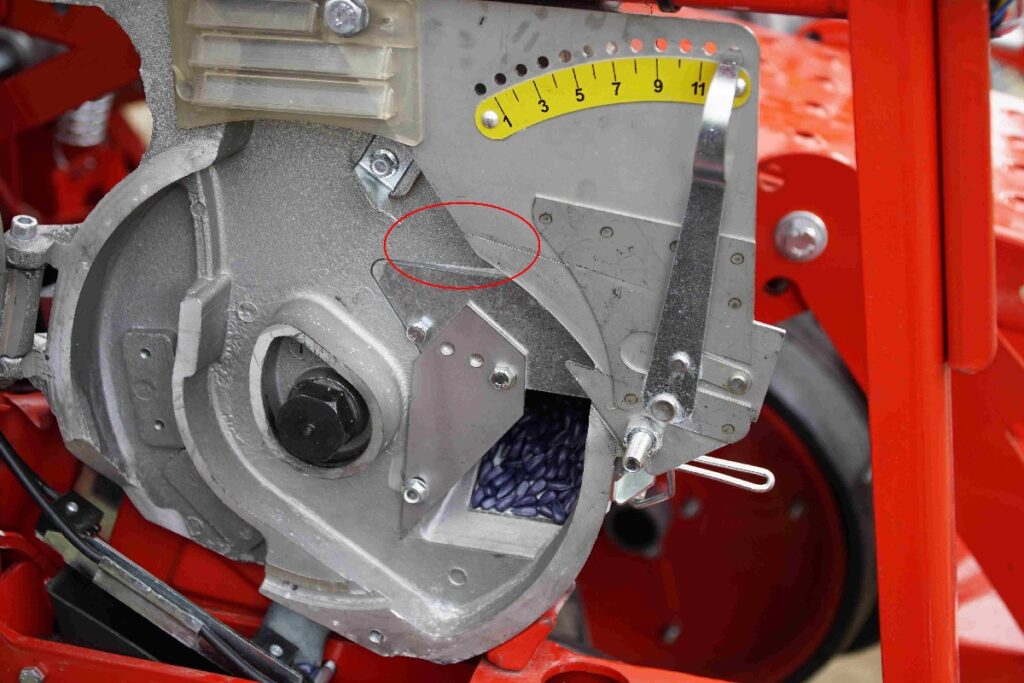

When working with such a machine, you should pay attention to the correct individualization of seeds. This is done with the selector lever, which, when correctly set, allows the seeds to be sown singly and not double. It has a scale, where 1 is the most aggressive setting – the nose of the selector is then at maximum extension.

The standard equipment list of the precision seed drill includes a set of two sowing discs. The version with 26 4.8-mm holes is used for maize seed. On the other hand, the disc with 20 3-mm precision bores is designed for sunflower seeds. On request, a range of other discs is available for sowing, for example, beetroot, soya or rape seeds. When changing discs, remember to do so with the system free of seeds. Otherwise they will fly out onto the ground and have to be collected. If the discs need to be changed after the hoppers have been filled with them, the solution is to drain them through the feed opening at the base of the sowing unit.

What quantity of sunflowers per ha ? HMS Pinadisc 4 row seed drill..

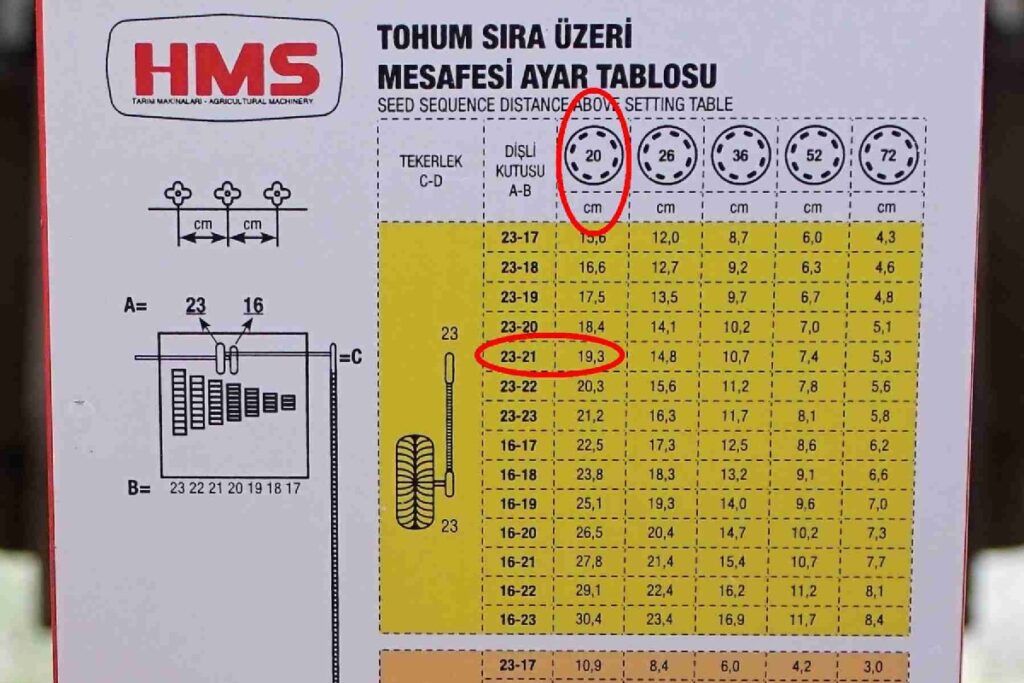

The most important operation to carry out on a precision seed drill is to set the plant (seed) density. On the HMS 4F Pinadisc Jumbo, this is not difficult. The first step is to read the information in the table about what the distance between the seeds in the row should be for their expected density per hectare. For about 70,000, with a row spacing of 75 cm, this is about 19 cm.

We then proceed to set the appropriate gear ratio in the chain gear box. This is located exactly in the middle of the seed drill between the sections. Once the cover is opened, you can quickly determine which gear ratio to set. It doesn’t hurt that there is no Polish language, because the table is presented very intuitively. Knowing the distance of the seed in the row (in our case, approx. 19 cm) and which sowing discs will be used (how many holes they have), we can read off the ratio to be set. In the table, for a 20-hole disc, the closest value to 19 cm is 19.3. Next to it, in the same row of the table on the far left, is the numerical value 23-21. The first indicates the upper and the second the lower chain wheel. It is onto this, after releasing the tensioner, that the drive chain is fitted. This concludes the entire seed setting procedure. Of course, before closing the box cover, you must remember to re-tension the chain..

The HMS precision seed drill has a controller with information reading from the MC DORADO 12000 photocells.

As befits a modern precision seed drill, the HMS 4F Pinadisc Jumbo has photocells fitted as standard. If there is a problem maintaining the assumed seed sowing rate in one of the sections, the tractor operator will immediately receive a message. There will be an audible and light signal at the post of the section where the blockage has occurred or the seed has run out. The operation of the photocells is made possible by a computer from the Italian brand MC Electronics. This is the Dorado 1200 controller, whose colour screen displays information of the seed drill and its operating parameters. In addition to the aforementioned monitoring of the seed flow in individual sections, it provides information about the current number of seeds sown and the intervals between them. In addition, it allows the total area sown to be summed up within a sub-counter and a total counter.

The braking and pressing wheel makes a difference

Let’s go back to the seed sowing system. After they have fallen off the sowing disc, they fall into the soil in the furrow prepared by the double disc coulters. There, they come under the ‘care’ of a rubber braking and pressing wheel, which stops them, presses them down and, as a result, causes them to be initially buried in the soil. This wheel has a simple spring-loaded pressure adjustment. It can be set weaker or stronger. It is an often underestimated piece of equipment on a precision seed drill that makes the proverbial difference. Correctly adjusted, it maintains precision when sowing at high speeds. The manufacturer recommends sowing at speeds of up to 8 km/h. In practice, however, it is known that a well-adjusted machine of this type also maintains a high level of work quality at 10 km/h. The last working element of the HMS 4F Pinadisc Jumbo seed drill is the angled harrow wheels. This can, of course, be varied by means of a lever, which influences the shape and size of the soil strip above the seeded area. The pressure of these wheels is also adjustable. This is achieved with an arm that allows you to increase or decrease the spring tension..

HMS 4-row seed drill – Machines available immediately

In our opinion the HMS 4F Pinadisc Jumbo precision seed drill is a machine worth considering. It offers everything a modern pneumatic precision seed drill should have in its budget version. The machine is robustly built, equipped with a stainless steel fertilizer tank, and is designed to last for many years..

In addition to the 4-row HMS precision seed drill, the Lupus company also offers 6-row models. These machines come in versions without a fertilizer tank or with a 1000-liter fertilizer tank on a semi-telescopic or telescopic frame. The fully telescopic versions allow for row spacing adjustments of 45, 50, 55, 60, 65, 70, and 75 cm.

MAIZE SEED DRILL – WE INVITE YOU TO EXPLORE OUR OFFER- CLICK HERE

źródło: Autor: Krzysztof Płocki, wwww.traktor24.pl