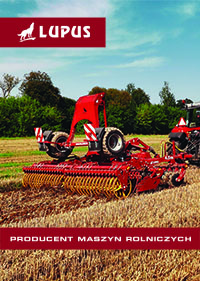

Tine Harrow LUPUS

Heavy Tine Harrows LUPUS (5, 7, and 9-section)

BUY DIRECTLY FROM THE MANUFACTURER

LUPUS – Factory & Showroom: ul. Mleczarska 6, 06-400 Ciechanów, POLAND

About us: We are a manufacturer operating in the agricultural sector since 2008. We organize international transport directly to your address. Transport costs are calculated individually based on your location.

CONTACT & ORDERS: Feel free to contact us to arrange the details: 📞 WhatsApp: +48 798 988 179 📧 E-mail: export@fhlupus.pl

Heavy tine harrows are fundamental agricultural machines that should not be missing from any farm focused on optimal soil preparation. Unlike light "grass harrows," LUPUS machines are designed for heavy-duty tasks. They serve for shallow tillage, aiming at final field preparation before seeding, as well as mechanical care of already sown crops. Their versatility makes them indispensable in many field operations, contributing to healthy plant growth and abundant yields. Field tine harrows play a crucial role in the soil preparation process. Their main applications include: Field Surface Leveling: After ploughing or other treatments, heavy harrows effectively break remaining soil clods and level unevenness, creating a smooth and uniform surface, ideal for seeding. Crushing and Loosening: The heavy harrow sections (90 kg per section!) allow tines to penetrate the topsoil layer, breaking compacted lumps and creating a looser structure. This improves soil aeration and facilitates seed emergence. Mechanical Weed Control: Shallow cultivation with harrows effectively removes young weeds, limiting competition for crops and reducing the need for later herbicide use. Residue and Fertilizer Mixing: Harrows help in the even distribution of fertilizers across the field surface and shallow mixing of crop residues, accelerating their decomposition. Moisture Management: They break the soil capillarity, stopping water evaporation – a crucial feature during dry seasons. By choosing heavy field tine harrows, you invest in a tool that will significantly improve the quality of your field and increase the efficiency of your farm. When deciding on tractor tine harrows, it is important to find the perfect combination of quality and functionality. We offer a wide selection of harrows that meet the expectations of both medium and large farms. Our offer includes: Hydraulic Folding Harrows: An ideal solution for owners of large acreages. The hydraulic system allows for quick folding and unfolding for transport, increasing comfort and work efficiency. Various Working Widths: From 5.0 m models providing precision on smaller fields, up to 9.0 m wide harrows for maximum efficiency on large surfaces. Equipment Options: Possibility to equip harrows with a rear scraper bar or string roller, which allows for even better soil finishing. As a tine harrow manufacturer with an established position in the market, LUPUS guarantees the highest quality. Our machines, designed and manufactured in Poland (Ciechanów), are the result of our own design and construction base and are produced from premium materials (S355 steel, thick-walled profiles). Thanks to this, LUPUS harrows are extremely durable and reliable in all field conditions. Check our models: Heavy Tine Harrows LUPUS (5, 7, and 9-section) The classic heavy solution. By choosing LUPUS heavy tine harrows, you gain not only proven equipment but also direct contact with the manufacturer. This means fast service, constant availability of spare parts "off-the-shelf," and elimination of middleman margins.

Heavy Tine Harrows – The Ultimate Tool for Soil Preparation and Weed Control

What are Heavy Tine Harrows Used For? Key to Success in Agriculture

Choose the Perfect Tractor Tine Harrow: Price and Quality

LUPUS Heavy Tine Harrows – Robustness and Innovation Direct from the Manufacturer